Related Hydraulic Hammer

|

model

|

total weight

|

length

|

diameterof tool

|

suitable carrier

|

|

unit

|

kg / lbs

|

mm

|

mm inch

|

ton

|

|

EDT100

|

53 117

|

918/1086/1190

|

10 1.57

|

0.8-2.5

|

|

EDT200

|

71 156

|

1090/1235/1331

|

45 1.77

|

1.2-3.0

|

|

EDT300

|

89 196

|

1178/1344/1417

|

53 2.08

|

2.5-4.5

|

|

EDT400

|

156 343

|

1373/684/1660

|

68 2.68

|

4-7

|

|

EDT400A

|

165 363

|

1373/1684/1660

|

68 2.68

|

4-7

|

|

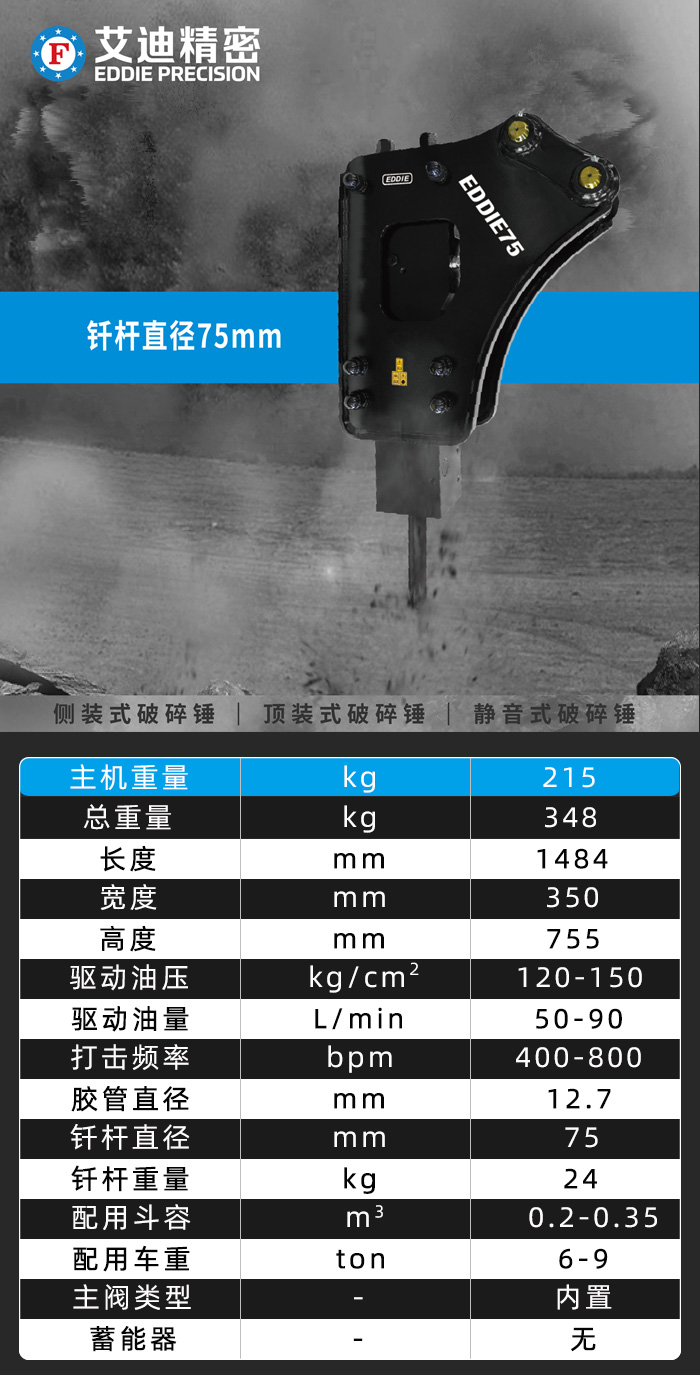

EDT430

|

214 471

|

1515/1706/1712

|

75 2.95

|

6-9

|

|

EDT435

|

215 473

|

1630/1738/1717

|

75/80 2.95/3.15

|

6-9

|

|

EDT435A

|

225 295

|

1630/1738/1717

|

75/80 2.95/3.15

|

6-9

|

|

EDT450

|

282 620

|

1735/2120/2074

|

85 3.35

|

7-14

|

|

EDT450A

|

301 662

|

1735/2120/2074

|

85 3.35

|

7-14

|

|

EDT800

|

479 1054

|

1994/2387/2354

|

100 3.94

|

10-15

|

|

EDT800A

|

503 1107

|

1994/2387/2354

|

100 3.94

|

10-15

|

|

EDT1600

|

620 1364

|

2285/2673/2578

|

125 4.92

|

15-18

|

|

EDT2000

|

850 1870

|

2423/2900/2847

|

135 5.31

|

18-26

|

|

EDT2000F

|

846 1861

|

2427/2656/2646

|

135 5.31

|

18-26

|

|

EDT2200

|

920 2024

|

2480/2866/2793

|

140 5.51

|

18-26

|

|

EDT2200A

|

956 2103

|

2480/2866/2793

|

140 5.51

|

18-26

|

|

EDT3000

|

1092 2402

|

2640/2897/3002

|

150 5.91

|

27-35

|

|

EDT4500

|

1960 4300

|

3184/3812/3723

|

175 6.89

|

35-40

|

|

EDT8000

|

2663 5842

|

3420/4021/-

|

195 7.68

|

45-60

|

Logo de machines Tonkee

Logo de machines Tonkee